(!)由於 Microsoft 2022 年 6 月 15 日終止支援,Internet Explorer 11 不屬於本網站之推薦環境。

商品分類

- 2024/12/28(六)~2025/1/5(日)適逢日本年假期間暫停出貨。 建議提早備貨以減少對交期的影響, 同時預防連假後出貨量遽增產生延遲。

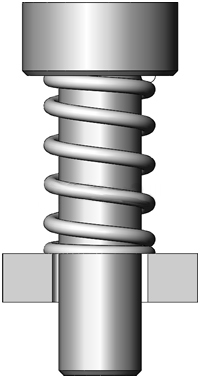

【經濟型】壓縮彈簧 外徑基準不鏽鋼 輕荷重型

標準價格:◆◆12元-49元/個◆◆

※經濟型商品無對應RoHS。

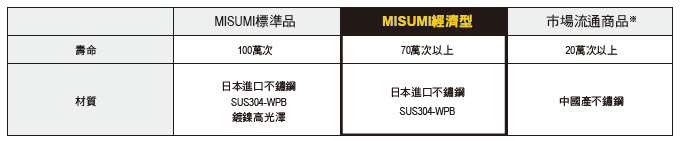

●經濟型壓縮彈簧採用日本進口材料,透過海外製造大幅降低成本,MISUMI品質管控性能優於一般彈簧,價格更實惠。

●本彈簧為外徑基準型彈簧。請注意,此產品以外徑公差為優先進行製作。

●不鏽鋼彈簧亦具有磁性。請特別注意。

(i)請注意

- 經濟型產品,請訂購10個以上。

型號

商品篩選結果為1件時,會顯示商品型號。

本頁所標註的為參考用的標準出貨日。確切的預定到貨日請以訂購完成通知書的資訊為準。

尺寸圖

尺寸圖

材質:SUS304-WPB彈簧係數:±10%

規格表

■ C-UL:Fmax. (容許壓縮量)=L×40%

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。 | 型式 | d | 貼緊長度 | F max. | N {kgf} max. | ||

Type Type D- D- L L | ||||||

| C-UL 2- | 5* | 0.20 | 1.65 | 2 | 0.98 | {0.1} |

| 10* | 0.26 | 5.07 | 4 | 1.96 | {0.2} | |

| 15* | 0.26 | 5.07 | 6 | 2.94 | {0.3} | |

| C-UL 3- | 5* | 0.30 | 2.00 | 2 | 2.0 | {0.2} |

| 10* | 0.35 | 3.70 | 4 | 3.9 | {0.4} | |

| 15* | 0.40 | 6.60 | 6 | 5.9 | {0.6} | |

| 20* | 0.40 | 6.60 | 8 | 7.8 | {0.8} | |

| 25* | 0.45 | 11.70 | 10 | 9.8 | {1.0} | |

| 30* | 0.45 | 11.70 | 12 | 11.8 | {1.2} | |

| C-UL 4- | 5* | 0.35 | 2.10 | 2 | 2.0 | {0.2} |

| 10* | 0.45 | 5.30 | 4 | 3.9 | {0.4} | |

| 15* | 0.45 | 5.30 | 6 | 5.9 | {0.6} | |

| 20* | 0.50 | 8.00 | 8 | 7.8 | {0.8} | |

| 25* | 0.50 | 8.00 | 10 | 9.8 | {1.0} | |

| 30* | 0.55 | 12.70 | 12 | 11.8 | {1.2} | |

| 40 | 0.60 | 19.80 | 16 | 15.7 | {1.6} | |

| C-UL 5- | 5* | 0.40 | 2.20 | 2 | 2.0 | {0.2} |

| 10* | 0.50 | 4.75 | 4 | 3.9 | {0.4} | |

| 15* | 0.50 | 4.75 | 6 | 5.9 | {0.6} | |

| 20* | 0.55 | 6.88 | 8 | 7.8 | {0.8} | |

| 25* | 0.55 | 6.88 | 10 | 9.8 | {1.0} | |

| 30 | 0.65 | 14.95 | 12 | 11.8 | {1.2} | |

| 40 | 0.65 | 14.95 | 16 | 15.7 | {1.6} | |

| C-UL 6- | 5* | 0.45 | 2.30 | 2 | 2.0 | {0.2} |

| 10* | 0.55 | 4.40 | 4 | 3.9 | {0.4} | |

| 15* | 0.55 | 4.40 | 6 | 5.9 | {0.6} | |

| 20 | 0.65 | 8.50 | 8 | 7.8 | {0.8} | |

| 25 | 0.65 | 8.50 | 10 | 9.8 | {1.0} | |

| 30 | 0.70 | 12.60 | 12 | 11.8 | {1.2} | |

| 35 | 0.70 | 12.60 | 14 | 13.7 | {1.4} | |

| C-UL 8- | 10 | 0.65 | 4.60 | 4 | 3.9 | {0.4} |

| 15 | 0.75 | 8.30 | 6 | 5.9 | {0.6} | |

| 20 | 0.75 | 8.30 | 8 | 7.8 | {0.8} | |

| 25 | 0.75 | 8.30 | 10 | 9.8 | {1.0} | |

| 30 | 0.80 | 10.40 | 12 | 11.8 | {1.2} | |

| 35 | 0.80 | 10.40 | 14 | 13.7 | {1.4} | |

| 40 | 0.80 | 10.40 | 16 | 15.7 | {1.6} | |

| C-UL 10- | 10 | 0.75 | 4.70 | 4 | 3.9 | {0.4} |

| 15 | 0.80 | 6.20 | 6 | 5.9 | {0.6} | |

| 20 | 0.80 | 6.20 | 8 | 7.8 | {0.8} | |

| 25 | 0.90 | 9.50 | 10 | 9.8 | {1.0} | |

| 30 | 0.90 | 9.50 | 12 | 11.8 | {1.2} | |

| 35 | 0.90 | 9.50 | 14 | 13.7 | {1.4} | |

| C-UL 12- | 25 | 1.0 | 10,0 | 10 | 9.8 | {1.0} |

| C-UL 13- | 20 | 1.0 | 8.25 | 8 | 7.8 | {0.8} |

| 30 | 1.1 | 12.1 | 12 | 11.8 | {1.2} | |

| C-UL 20- | 30 | 1.7 | 12.8 | 12 | 35.3 | {3.6} |

■ C-UTT:Fmax. (容許壓縮量)=L×Fa%

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。| 型式 | d | 貼緊長度 | F max. | N {kgf} max. | Fa% | ||

Type Type D- D- L L | |||||||

| C-UTT 3- | 5* | 0.35 | 2.8 | 2 | 2.9 | {0.3} | 40 |

| 10* | 0.40 | 4.8 | 4 | 5.9 | {0.6} | ||

| 15* | 0.45 | 8.3 | 6 | 8.8 | {0.9} | ||

| 20* | 0.45 | 8.3 | 6 | 8.8 | {0.9} | 30 | |

| C-UTT 4- | 5* | 0.40 | 2.6 | 2 | 2.9 | {0.3} | 40 |

| 10* | 0.45 | 3.9 | 4 | 5.9 | {0.6} | ||

| 15* | 0.50 | 6.0 | 6 | 8.8 | {0.9} | ||

| 20* | 0.55 | 9.4 | 8 | 11.8 | {1.2} | ||

| 30 | 0.60 | 14.4 | 10 | 14.7 | {1.5} | 33 | |

| C-UTT 5- | 5* | 0.45 | 2.6 | 2 | 2.9 | {0.3} | 40 |

| 10* | 0.50 | 3.6 | 4 | 5.9 | {0.6} | ||

| 15 | 0.60 | 7.5 | 6 | 8.8 | {0.9} | ||

| 20 | 0.60 | 7.5 | 8 | 11.8 | {1.2} | ||

| 25 | 0.65 | 10.7 | 10 | 14.7 | {1.5} | ||

| 30 | 0.70 | 15.4 | 12 | 17.7 | {1.8} | ||

| C-UTT 6- | 5* | 0.50 | 2.4 | 2 | 3.9 | {0.4} | 40 |

| 10 | 0.60 | 4.2 | 4 | 7.8 | {0.8} | ||

| 15 | 0.70 | 7.4 | 6 | 11.8 | {1.2} | ||

| 20 | 0.70 | 7.4 | 8 | 15.7 | {1.6} | ||

| 25 | 0.80 | 13.6 | 10 | 19.6 | {2.0} | ||

| 30 | 0.80 | 13.6 | 12 | 23.5 | {2.4} | ||

| 35 | 0.85 | 17.5 | 14 | 27.5 | {2.8} | ||

| C-UTT 8- | 10 | 0.75 | 5.3 | 4 | 7.8 | {0.08} | 40 |

| 15 | 0.75 | 5.3 | 6 | 11.8 | {1.2} | ||

| 20 | 0.90 | 10.4 | 8 | 15.7 | {1.6} | ||

| 25 | 0.90 | 10.4 | 10 | 19.6 | {2.0} | ||

| 30 | 1.00 | 17.0 | 12 | 23.5 | {2.4} | ||

| 35 | 1.00 | 17.0 | 14 | 27.5 | {2.8} | ||

| 40 | 1.00 | 17.0 | 16 | 31.4 | {3.2} | ||

| C-UTT 10- | 10 | 0.85 | 5.1 | 4 | 7.8 | {0.8} | 40 |

| 15 | 0.85 | 5.1 | 6 | 11.8 | {1.2} | ||

| 20 | 1.00 | 9.5 | 8 | 15.7 | {1.6} | ||

| 25 | 1.00 | 9.5 | 10 | 19.6 | {2.0} | ||

| 30 | 1.10 | 14.3 | 12 | 23.5 | {2.4} | ||

| 35 | 1.10 | 14.3 | 14 | 27.5 | {2.8} | ||

| C-UTT 13- | 15 | 1.0 | 5.75 | 6 | 11.8 | {1.2} | 40 |

| 20 | 1.2 | 10.5 | 8 | 15.7 | {1.6} | ||

| 25 | 1.2 | 10.5 | 10 | 19.6 | {2.0} | ||

| 30 | 1.3 | 15.0 | 12 | 23.5 | {2.4} | ||

| 35 | 1.3 | 15.0 | 14 | 27.5 | {2.8} | ||

| 40 | 1.4 | 20.3 | 16 | 31.4 | {3.2} | ||

| C-UTT 16- | 15 | 1.2 | 7.2 | 6 | 11.8 | {1.2} | 40 |

| 35 | 1.5 | 16.5 | 14 | 27.5 | {2.8} | ||

kgf (荷重) =N/mm (彈簧常數) ×0.101972×F (壓縮量)

{kgf}=N×0.101972

{kgf}=N×0.101972

有*符號者,兩端端面皆無研磨加工。

有*符號者,兩端端面皆無研磨加工。 外徑基準型優先保證外徑,內徑僅作為參考。

外徑基準型優先保證外徑,內徑僅作為參考。 貼緊長度為參考值。生產批號不同的產品會有一些誤差。

貼緊長度為參考值。生產批號不同的產品會有一些誤差。 請務必在容許壓縮量F max.(mm)的範圍內使用,若超過容許壓縮量時,彈簧可能會變形或使用幾次就損毀。

請務必在容許壓縮量F max.(mm)的範圍內使用,若超過容許壓縮量時,彈簧可能會變形或使用幾次就損毀。 圈數為參考值。生產批號不同的產品會有一些誤差。

圈數為參考值。生產批號不同的產品會有一些誤差。總圈數=緊貼長度 ÷ 線徑(d)-1

有效圈數=總圈數-2

商品特點

● MISUMI壓縮彈簧有別於市售一般彈簧,更加精準精細化,分為內徑基準型和外徑基準型。

外徑基準型以外徑公差為製作的優先考量,內徑基準型則以內徑公差為製作的優先考量。

● 根據安裝實際情況選擇合適的彈簧種類,具體內外徑公差請參考資料刊載內容。

● 如果希望使用較多次數時,建議在容許壓縮量Fmax.的70%以內使用。

外徑基準型以外徑公差為製作的優先考量,內徑基準型則以內徑公差為製作的優先考量。

● 根據安裝實際情況選擇合適的彈簧種類,具體內外徑公差請參考資料刊載內容。

● 如果希望使用較多次數時,建議在容許壓縮量Fmax.的70%以內使用。

※實驗數據系本公司檢測所得,僅供參考 ※市場流通品,系本公司自網路或實體市場隨機採購的同類產品 |  內徑基準型圓線彈簧安裝示意圖 |

注意事項

● 使用溫度

SWP—A製……常溫 (0〜40℃)

不鏽鋼製……-10〜100℃

彈簧用油回火線……常溫 (0〜40℃)

*超過上述溫度範圍的環境下使用,荷重值會依條件不同而有所衰減。

*需在室外等有冷熱溫差及濕氣的環境下使用時.建議選擇不鏽鋼製品。

*另有耐熱用彈簧可選用。詳情請參照《塑膠模具用標準零件型錄》。

● 不鏽鋼製彈簧也有磁性。請務必注意。

SWP—A製……常溫 (0〜40℃)

不鏽鋼製……-10〜100℃

彈簧用油回火線……常溫 (0〜40℃)

*超過上述溫度範圍的環境下使用,荷重值會依條件不同而有所衰減。

*需在室外等有冷熱溫差及濕氣的環境下使用時.建議選擇不鏽鋼製品。

*另有耐熱用彈簧可選用。詳情請參照《塑膠模具用標準零件型錄》。

● 不鏽鋼製彈簧也有磁性。請務必注意。

相關商品

|  |

| 【經濟型】圓線彈簧 外徑基準不鏽鋼型 極輕荷重用 彈簧常數0.05~0.98N/mm | 【經濟型】圓線彈簧 外徑基準不鏽鋼型 重荷重用 彈簧常數2.0~14.7N/mm |

| 推薦理由:MISUMI經濟型圓線彈簧 外徑基準型 極輕荷重用 | 推薦理由:MISUMI經濟型圓線彈簧 外徑基準型 重荷重用 |

3D預覽型號

尚未指定完整型號,因此無法執行CAD檔案下載及3D預覽

- ※ 欲執行CAD檔案下載及3D預覽時,需指定完整型號。

- 請於左側「篩選規格・尺寸」確認完整型號,然後執行CAD檔案下載及3D預覽。

Loading...

| 型號 | 數量折扣 | 標準 出貨日 | 容許荷重(範圍指定) (N) | 端面狀態 | 最大荷重 (N) | 最大荷重時高度(自由長度-容許壓縮量) (mm) | 自由長度 L (mm) | 外徑 D(或是D1) (φ) | 內徑 D-2d(或是D) (φ) | 彈簧常數 (N/mm) | 線徑 (φ) | 貼緊長度 (mm) | 總圈數 | 容許壓縮量 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 24 | 40 | 4 | 2.8 | 0.98 | 0.6 | 19.8 | 32 | 16 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 18 | 30 | 5 | 3.7 | 0.98 | 0.65 | 14.95 | 22 | 12 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 24 | 40 | 5 | 3.7 | 0.98 | 0.65 | 14.95 | 22 | 16 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 12 | 20 | 6 | 4.7 | 0.98 | 0.65 | 8.5 | 12.1 | 8 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 9.8 | 15 | 25 | 6 | 4.7 | 0.98 | 0.65 | 8.5 | 12.1 | 10 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 18 | 30 | 6 | 4.6 | 0.98 | 0.7 | 12.6 | 17 | 12 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 13.7 | 21 | 35 | 6 | 4.6 | 0.98 | 0.7 | 12.6 | 17 | 14 | ||

| 當日可能 | 1.51~4.50 | 有研磨 | 3.9 | 6 | 10 | 8 | 6.7 | 0.98 | 0.65 | 4.6 | 6.1 | 4 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 5.9 | 9 | 15 | 8 | 6.5 | 0.98 | 0.75 | 8.3 | 10.1 | 6 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 12 | 20 | 8 | 6.5 | 0.98 | 0.75 | 8.3 | 10.1 | 8 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 9.8 | 15 | 25 | 8 | 6.5 | 0.98 | 0.75 | 8.3 | 10.1 | 10 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 18 | 30 | 8 | 6.4 | 0.98 | 0.8 | 10.4 | 12 | 12 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 13.7 | 21 | 35 | 8 | 6.4 | 0.98 | 0.8 | 10.4 | 12 | 14 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 24 | 40 | 8 | 6.4 | 0.98 | 0.8 | 10.4 | 12 | 16 | ||

| 當日可能 | 1.51~4.50 | 有研磨 | 3.9 | 6 | 10 | 10 | 8.5 | 0.98 | 0.75 | 4.7 | 5.3 | 4 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 5.9 | 9 | 15 | 10 | 8.4 | 0.98 | 0.8 | 6.2 | 6.8 | 6 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 12 | 20 | 10 | 8.4 | 0.98 | 0.8 | 6.2 | 6.8 | 8 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 9.8 | 15 | 25 | 10 | 8.2 | 0.98 | 0.9 | 9.5 | 9.6 | 10 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 18 | 30 | 10 | 8.2 | 0.98 | 0.9 | 9.5 | 9.6 | 12 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 13.7 | 21 | 35 | 10 | 8.2 | 0.98 | 0.9 | 9.5 | 9.6 | 14 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 9.8 | 15 | 25 | 12 | 10 | 0.98 | 1 | 9 | 9 | 10 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 12 | 20 | 13 | 11 | 0.98 | 1 | 8.25 | 7.3 | 8 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 18 | 30 | 13 | 10.8 | 0.98 | 1.1 | 12.1 | 10 | 12 | ||

| 當日可能 | 30.01~50.00 | 有研磨 | 35.3 | 18 | 30 | 20 | 16.6 | 2.9 | 1.7 | 12.8 | 6.5 | 12 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 14.7 | 20 | 30 | 4 | 2.8 | 1.5 | 0.6 | 14.4 | 23 | 10 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 8.8 | 9 | 15 | 5 | 3.8 | 1.5 | 0.6 | 7.5 | 11.5 | 6 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 12 | 20 | 5 | 3.8 | 1.5 | 0.6 | 7.5 | 11.5 | 8 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 14.7 | 15 | 25 | 5 | 3.7 | 1.5 | 0.65 | 10.7 | 15.5 | 10 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 17.7 | 18 | 30 | 5 | 3.6 | 1.5 | 0.7 | 15.4 | 21 | 12 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 6 | 10 | 6 | 4.8 | 2 | 0.6 | 4.2 | 6 | 4 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 9 | 15 | 6 | 4.6 | 2 | 0.7 | 7.4 | 9.6 | 6 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 12 | 20 | 6 | 4.6 | 2 | 0.7 | 7.4 | 9.6 | 8 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 19.6 | 15 | 25 | 6 | 4.4 | 2 | 0.8 | 13.6 | 16 | 10 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 23.5 | 18 | 30 | 6 | 4.4 | 2 | 0.8 | 13.6 | 16 | 12 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 27.5 | 21 | 35 | 6 | 4.3 | 2 | 0.85 | 17.5 | 19.6 | 14 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 6 | 10 | 8 | 6.5 | 2 | 0.75 | 5.3 | 6.1 | 4 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 9 | 15 | 8 | 6.5 | 2 | 0.75 | 5.3 | 6.1 | 6 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 12 | 20 | 8 | 6.2 | 2 | 0.9 | 10.4 | 10.6 | 8 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 19.6 | 15 | 25 | 8 | 6.2 | 2 | 0.9 | 10.4 | 10.6 | 10 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 23.5 | 18 | 30 | 8 | 6 | 2 | 1 | 17 | 16 | 12 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 27.5 | 21 | 35 | 8 | 6 | 2 | 1 | 17 | 16 | 14 | ||

| 當日可能 | 30.01~50.00 | 有研磨 | 31.4 | 24 | 40 | 8 | 6 | 2 | 1 | 17 | 16 | 16 | ||

| 當日可能 | 4.51~8.50 | 有研磨 | 7.8 | 6 | 10 | 10 | 8.3 | 2 | 0.85 | 5.1 | 5 | 4 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 9 | 15 | 10 | 8.3 | 2 | 0.85 | 5.1 | 5 | 6 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 12 | 20 | 10 | 8 | 2 | 1 | 9.5 | 8.5 | 8 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 19.6 | 15 | 25 | 10 | 8 | 2 | 1 | 9.5 | 8.5 | 10 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 23.5 | 18 | 30 | 10 | 7.8 | 2 | 1.1 | 14.3 | 12 | 12 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 27.5 | 21 | 35 | 10 | 7.8 | 2 | 1.1 | 14.3 | 12 | 14 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 9 | 15 | 13 | 11 | 2 | 1 | 5.75 | 4.8 | 6 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 15.7 | 12 | 20 | 13 | 10.6 | 2 | 1.2 | 10.5 | 7.8 | 8 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 19.6 | 15 | 25 | 13 | 10.6 | 2 | 1.2 | 10.5 | 7.8 | 10 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 23.5 | 18 | 30 | 13 | 10.4 | 2 | 1.3 | 15 | 10.5 | 12 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 27.5 | 21 | 35 | 13 | 10.4 | 2 | 1.3 | 15 | 10.5 | 14 | ||

| 當日可能 | 30.01~50.00 | 有研磨 | 31.4 | 24 | 40 | 13 | 10.2 | 2 | 1.4 | 20.3 | 13.5 | 16 | ||

| 當日可能 | 8.51~16.00 | 有研磨 | 11.8 | 9 | 15 | 16 | 13.6 | 2 | 1.2 | 7.2 | 5 | 6 | ||

| 當日可能 | 16.01~30.00 | 有研磨 | 27.5 | 21 | 35 | 16 | 13 | 2 | 1.5 | 16.5 | 10 | 14 |

Loading...

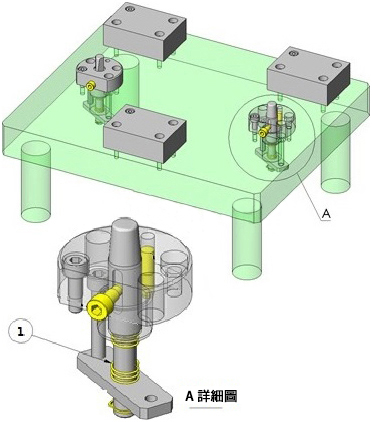

使用範例

孔基準定位機構

以孔基準對工件進行定位的機構。

透過角錐銷消除各工件孔公差產生的偏移,可減少定位時的鬆脫。

選擇壓縮彈簧以便自定位接觸工件開始移動

以孔基準對工件進行定位的機構。

透過角錐銷消除各工件孔公差產生的偏移,可減少定位時的鬆脫。

選擇壓縮彈簧以便自定位接觸工件開始移動

基本資訊

| 材質 | SUS304-WPB |

|---|

篩選規格・尺寸

-

類型

- C-UL

- C-UTT

-

容許荷重(範圍指定)(N)

- ~1.50

- 1.51~4.50

- 4.51~8.50

- 8.51~16.00

- 16.01~30.00

- 30.01~50.00

-

最大荷重(N)

-

最大荷重時高度(自由長度-容許壓縮量)(mm)

-

自由長度 L(mm)

-

外徑 D(或是D1)(φ)

-

內徑 D-2d(或是D)(φ)

-

彈簧常數(N/mm)

-

線徑(φ)

-

貼緊長度(mm)

-

總圈數

-

容許壓縮量(mm)

-

端面狀態

- 有研磨

- 無研磨

-

CAD檔案

- 2D

- 3D

用出貨日篩選

-

- 全選

- 當日可能

可指定追加工

- 因有部分型號的規格・尺寸無法完全顯示,詳細資訊請參照 廠牌產品型錄 。

常見問題 ( FAQ )

- 質問: 經濟型壓縮彈簧的壽命是多少?

- 回答: 因為壽命在一定程度上有個體偏差,具體安裝情況複雜因此關於壓縮彈簧的壽命次數,雖然很遺憾但是沒有具體的試驗數值作為參考。使用次數因使用溫度或者環境、變形量而發生變化。要增加使用次數,建議在容許位移量Fmax.的70%以下使用。

- 質問: 無彈簧導軌的使用會對彈簧造成什麼影響?

- 回答: 沒有彈簧導軌的情況下使用,彈簧會有屈曲、軀幹彎曲等發生,彎曲內側局部產生高應力,導致折損。為了保證彈簧使用壽命請使用軸、外徑導軌等安裝彈簧。※基本上,在內徑側導軌中軸從上表面貫穿下面使用是比較理想的。

- 質問: 超過最大位移量30萬次的使用(貼緊壓緊長度附近使用時)會對彈簧造成什麼影響?

- 回答: 超過最大位移量30萬次的使用(貼緊壓緊長度附近使用時)斷面會產生計算值以上的高應力折損。另外,在壓緊長度附近,有效卷部會慢慢貼緊,彈簧常數變高。因此請務必容許位移Fmax.(mm)範圍以內使用。

此分類還有這些商品

- 圓線彈簧 外徑基準 鋼琴線型WF・WL 【FA機械用標準零件】

- 圓線彈簧 外徑基準 不鏽鋼型UM・UH

- 【經濟型】壓縮彈簧 外徑基準不鏽鋼 極輕荷重型

- 【經濟型】壓縮彈簧 內徑基準不鏽鋼 輕荷重型

- Ultra Spring 壓縮線圈彈簧

- DS系列 壓縮線圈彈簧(按壓彈簧)

- 壓縮線圈彈簧

- 耐熱用彈簧

經常被一起購買的商品

技術支援服務

- FA用機械標準零件

- Tel:02-25703766 / FAX:02-25703767

- 與我們聯絡

請協助改善本網站

請協助改善本網站

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

個人資訊保護法・隱私權政策

非常感謝您的回答。

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

希望三住回覆的客戶請使用、 與我們聯絡

個人資訊保護法・隱私權政策