(!)由於 Microsoft 2022 年 6 月 15 日終止支援,Internet Explorer 11 不屬於本網站之推薦環境。

商品分類

不鏽鋼平齒輪 模數1

耐腐蝕性優異,且已實施螺牙孔加工,因此可快速使用的不鏽鋼平齒輪。

【特長】

・模數1.0,壓力角20(全齒深齒),材質為SUS304的不鏽鋼棒。

・齒輪精度等級為JIS B 1702-1(ISO)9級。

・形狀為K:棒狀、B:附單轂。

【用途】

・用於裝置的動力傳導、驅動、輸送部分。

型號

商品篩選結果為1件時,會顯示商品型號。

本頁所標註的為參考用的標準出貨日。確切的預定到貨日請以訂購完成通知書的資訊為準。

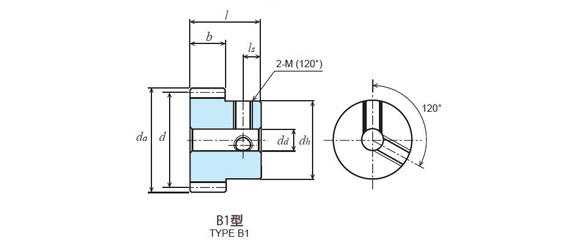

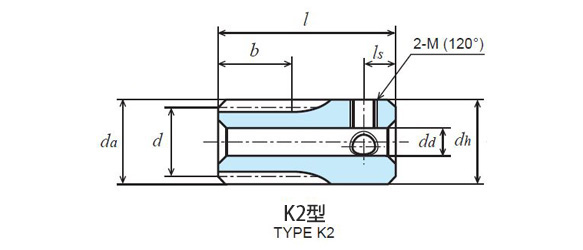

尺寸圖

B1型

K2型

產品規格

容許傳導動力表 彎曲強度(W)

| 型號 | 旋轉速度(min-1) | ||||||

|---|---|---|---|---|---|---|---|

| 10 | 100 | 200 | 400 | 800 | 1200 | 1500 | |

| S1SU14K*0806 | 1.77 | 17.71 | 35.41 | 70.82 | 141.64 | 212.46 | 261.67 |

| S1SU15K*0806 | 1.98 | 19.84 | 39.68 | 79.37 | 158.73 | 238.10 | 289.88 |

| S1SU16K*0806 | 2.20 | 22.02 | 44.04 | 88.08 | 176.16 | 264.03 | 318.05 |

| S1SU17B*0806 | 2.42 | 24.23 | 48.46 | 96.92 | 193.84 | 287.82 | 346.06 |

| S1SU18B*0806 | 2.65 | 26.47 | 52.94 | 105.88 | 211.76 | 311.52 | 373.85 |

| S1SU18B*1006 | 3.31 | 33.09 | 66.18 | 132.35 | 264.70 | 389.40 | 467.32 |

| S1SU20B*0806 | 3.11 | 31.08 | 62.16 | 124.32 | 248.64 | 359.14 | 429.43 |

| S1SU20B*1006 | 3.89 | 38.85 | 77.70 | 155.40 | 310.80 | 448.92 | 536.79 |

| S1SU21B*0806 | 3.34 | 33.40 | 66.81 | 133.62 | 267.24 | 382.52 | 456.60 |

| S1SU22B*0806 | 3.58 | 35.76 | 71.52 | 143.04 | 286.09 | 405.86 | 483.62 |

| S1SU24B*0806 | 4.05 | 40.52 | 81.04 | 162.07 | 323.88 | 451.79 | 536.54 |

| S1SU24B*1006 | 5.06 | 50.65 | 101.29 | 202.59 | 404.85 | 564.74 | 670.68 |

| S1SU25B*0806 | 4.29 | 42.93 | 85.86 | 171.72 | 341.02 | 474.52 | 562.62 |

| S1SU25B*1006 | 5.37 | 53.66 | 107.32 | 214.65 | 426.27 | 593.15 | 703.28 |

| S1SU26B*0806 | 4.54 | 45.36 | 90.71 | 181.43 | 358.07 | 497.04 | 588.38 |

| S1SU28B*0806 | 5.03 | 50.26 | 100.52 | 201.03 | 391.90 | 541.43 | 638.95 |

| S1SU28B*1006 | 6.28 | 62.82 | 125.65 | 251.29 | 489.88 | 676.79 | 798.68 |

| S1SU30B*0806 | 5.52 | 55.18 | 110.37 | 220.74 | 425.11 | 584.61 | 687.84 |

| S1SU30B*1006 | 6.90 | 68.98 | 137.96 | 275.92 | 531.39 | 730.76 | 859.80 |

| S1SU32B*0606 | 4.51 | 45.13 | 90.27 | 180.53 | 343.53 | 470.31 | 551.76 |

| S1SU34B*0606 | 4.89 | 48.91 | 97.82 | 195.64 | 367.87 | 501.44 | 586.65 |

| S1SU35B*0606 | 5.08 | 50.81 | 101.61 | 203.23 | 379.90 | 516.74 | 603.73 |

| S1SU36B*0608 | 5.27 | 52.71 | 105.42 | 210.85 | 391.84 | 531.86 | 620.57 |

| S1SU40B*0608 | 6.04 | 60.39 | 120.78 | 241.55 | 438.65 | 590.59 | 693.00 |

| S1SU42B*0608 | 6.43 | 64.26 | 128.51 | 257.02 | 461.49 | 618.92 | 733.00 |

| S1SU44B*0608 | 6.81 | 68.10 | 136.19 | 272.39 | 483.61 | 646.13 | 772.19 |

| S1SU45B*0608 | 7.00 | 70.04 | 140.08 | 280.17 | 494.67 | 659.68 | 791.90 |

| S1SU48B*0608 | 7.59 | 75.90 | 151.80 | 303.36 | 527.27 | 700.19 | 850.59 |

| S1SU50B*0608 | 7.98 | 79.82 | 159.65 | 317.05 | 548.54 | 732.84 | 889.33 |

| S1SU52B*0608 | 8.38 | 83.76 | 167.51 | 330.61 | 569.42 | 765.27 | 927.74 |

| S1SU54B*0608 | 8.77 | 87.70 | 175.40 | 344.05 | 589.94 | 797.50 | 965.84 |

| S1SU56B*0610 | 9.17 | 91.66 | 183.32 | 357.37 | 610.11 | 829.53 | 1,003.62 |

| S1SU60B*0610 | 9.96 | 99.60 | 199.19 | 383.62 | 649.37 | 892.91 | 1,078.17 |

| S1SU64B*0610 | 10.76 | 107.57 | 215.14 | 409.37 | 687.26 | 955.40 | 1,151.78 |

| S1SU70B*0610 | 11.96 | 119.58 | 239.15 | 447.06 | 741.67 | 1,047.46 | 1,266.18 |

| S1SU72B*0610 | 12.36 | 123.59 | 247.19 | 459.37 | 760.11 | 1,077.69 | 1,303.88 |

| S1SU80B*0610 | 13.97 | 139.71 | 279.42 | 507.42 | 848.29 | 1,196.75 | 1,452.49 |

| S1SU90B*0610 | 15.98 | 159.75 | 319.50 | 564.12 | 954.81 | 1,348.27 | 1,631.26 |

| S1SU100B*0610 | 18.00 | 180.02 | 357.51 | 618.54 | 1,059.38 | 1,497.28 | 1,806.04 |

| S1SU120B*0610 | 22.07 | 220.74 | 425.12 | 719.62 | 1,260.58 | 1,784.16 | 2,207.42 |

規格表

單位:mm

| 型號 | 齒數 z | 基準圓 直 徑 d | 齒尖圓 直 徑 da | 型 | 齒 寬 b | 孔 徑 dd(H8) | 轂 外 徑 dh | 轂 長 度 lh | 全 長 l | 螺 絲 | 重 量 W(g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2-M(120°) | ls | |||||||||||

| S1SU14K*0806 | 14 | φ14 | φ16 | K2 | 8 | φ6 | φ16 | 17 | 25 | 2-M4 | 4 | 30.4 |

| S1SU15K*0806 | 15 | φ15 | φ17 | K2 | 8 | φ6 | φ17 | 17 | 25 | 2-M4 | 4 | 35.3 |

| S1SU16K*0806 | 16 | φ16 | φ18 | K2 | 8 | φ6 | φ18 | 17 | 25 | 2-M4 | 4 | 40.5 |

| S1SU17B*0806 | 17 | φ17 | φ19 | B1 | 8 | φ6 | φ14 | 8 | 16 | 2-M4 | 4 | 19.9 |

| S1SU18B*0806 | 18 | φ18 | φ20 | B1 | 8 | φ6 | φ14 | 8 | 16 | 2-M4 | 4 | 21.7 |

| S1SU18B*1006 | 18 | φ18 | φ20 | B1 | 10 | φ6 | φ14 | 10 | 20 | 2-M4 | 4 | 27.2 |

| S1SU20B*0806 | 20 | φ20 | φ22 | B1 | 8 | φ6 | φ16 | 8 | 16 | 2-M4 | 4 | 28.3 |

| S1SU20B*1006 | 20 | φ20 | φ22 | B1 | 10 | φ6 | φ16 | 10 | 20 | 2-M4 | 4 | 35.5 |

| S1SU21B*0806 | 21 | φ21 | φ23 | B1 | 8 | φ6 | φ18 | 8 | 16 | 2-M4 | 4 | 33.5 |

| S1SU22B*0806 | 22 | φ22 | φ24 | B1 | 8 | φ6 | φ18 | 8 | 16 | 2-M4 | 4 | 35.7 |

| S1SU24B*0806 | 24 | φ24 | φ26 | B1 | 8 | φ6 | φ18 | 8 | 16 | 2-M4 | 4 | 40.3 |

| S1SU24B*1006 | 24 | φ24 | φ26 | B1 | 10 | φ6 | φ18 | 10 | 20 | 2-M4 | 4 | 50.6 |

| S1SU25B*0806 | 25 | φ25 | φ27 | B1 | 8 | φ6 | φ18 | 8 | 16 | 2-M4 | 4 | 42.7 |

| S1SU25B*1006 | 25 | φ25 | φ27 | B1 | 10 | φ6 | φ20 | 10 | 20 | 2-M4 | 4 | 58.2 |

| S1SU26B*0806 | 26 | φ26 | φ28 | B1 | 8 | φ6 | φ20 | 8 | 16 | 2-M4 | 4 | 48.9 |

| S1SU28B*0806 | 28 | φ28 | φ30 | B1 | 8 | φ6 | φ20 | 8 | 16 | 2-M4 | 4 | 54.2 |

| S1SU28B*1006 | 28 | φ28 | φ30 | B1 | 10 | φ6 | φ20 | 10 | 20 | 2-M4 | 4 | 68.1 |

| S1SU30B*0806 | 30 | φ30 | φ32 | B1 | 8 | φ6 | φ24 | 8 | 16 | 2-M4 | 4 | 68.5 |

| S1SU30B*0806 | 30 | φ30 | φ32 | B1 | 8 | φ6 | φ24 | 8 | 16 | 2-M4 | 4 | 68.5 |

| S1SU30B*1006 | 30 | φ30 | φ32 | B1 | 10 | φ6 | φ24 | 10 | 20 | 2-M4 | 4 | 86.0 |

| S1SU32B*0606 | 32 | φ32 | φ34 | B1 | 6 | φ6 | φ24 | 10 | 16 | 2-M4 | 4 | 69.1 |

| S1SU34B*0606 | 34 | φ34 | φ36 | B1 | 6 | φ6 | φ24 | 10 | 16 | 2-M4 | 4 | 74.0 |

| S1SU35B*0606 | 35 | φ35 | φ37 | B1 | 6 | φ6 | φ24 | 10 | 16 | 2-M4 | 4 | 76.6 |

| S1SU36B*0608 | 36 | φ36 | φ38 | B1 | 6 | φ8 | φ24 | 10 | 16 | 2-M4 | 4 | 76.6 |

| S1SU40B*0608 | 40 | φ40 | φ42 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 100.6 |

| S1SU42B*0608 | 42 | φ42 | φ44 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 106.7 |

| S1SU44B*0608 | 44 | φ44 | φ46 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 113.1 |

| S1SU45B*0608 | 45 | φ45 | φ47 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 116.5 |

| S1SU48B*0608 | 48 | φ48 | φ50 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 126.9 |

| S1SU50B*0608 | 50 | φ50 | φ52 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M4 | 4 | 134.2 |

| S1SU52B*0608 | 52 | φ52 | φ54 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M5 | 5 | 140.9 |

| S1SU54B*0608 | 54 | φ54 | φ56 | B1 | 6 | φ8 | φ28 | 10 | 16 | 2-M5 | 5 | 148.8 |

| S1SU56B*0610 | 56 | φ56 | φ58 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 160.6 |

| S1SU60B*0610 | 60 | φ60 | φ62 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 178.0 |

| S1SU64B*0610 | 64 | φ64 | φ66 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 196.5 |

| S1SU70B*0610 | 70 | φ70 | φ72 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 226.6 |

| S1SU72B*0610 | 72 | φ72 | φ74 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 237.2 |

| S1SU80B*0610 | 80 | φ80 | φ82 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 282.6 |

| S1SU90B*0610 | 90 | φ90 | φ92 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 346.1 |

| S1SU100B*0610 | 100 | φ100 | φ102 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 417.1 |

| S1SU120B*0610 | 120 | φ120 | φ122 | B1 | 6 | φ10 | φ30 | 10 | 16 | 2-M5 | 5 | 581.6 |

※SUS304 的產品未附固定螺絲。

| 型號 | 數量折扣 | 標準 出貨日 | 齒數 (齒) | 形狀 | 軸孔徑、軸徑 d (φ) | 齒寬 B (mm) | 形狀(詳細) |

|---|---|---|---|---|---|---|---|

| 4天~ | 17 | B形 | 6 | 8 | B1 | ||

| 4天~ | 18 | B形 | 6 | 8 | B1 | ||

| 4天~ | 18 | B形 | 6 | 10 | B1 | ||

| 4天~ | 20 | B形 | 6 | 8 | B1 | ||

| 4天~ | 24 | B形 | 6 | 8 | B1 | ||

| 6天~ | 25 | B形 | 6 | 8 | B1 | ||

| 5天~ | 26 | B形 | 6 | 8 | B1 | ||

| 4天~ | 28 | B形 | 6 | 8 | B1 | ||

| 4天~ | 30 | B形 | 6 | 8 | B1 | ||

| 4天~ | 30 | B形 | 6 | 10 | B1 | ||

| 6天~ | 32 | B形 | 6 | 6 | B1 | ||

| 4天~ | 35 | B形 | 6 | 6 | B1 | ||

| 4天~ | 36 | B形 | 8 | 6 | B1 | ||

| 4天~ | 40 | B形 | 8 | 6 | B1 | ||

| 33天~ | 44 | B形 | 8 | 6 | B1 | ||

| 4天~ | 50 | B形 | 8 | 6 | B1 | ||

| 4天~ | 60 | B形 | 10 | 6 | B1 | ||

| 4天~ | 70 | B形 | 10 | 6 | B1 | ||

| 6天~ | 80 | B形 | 10 | 6 | B1 | ||

| 4天~ | 90 | B形 | 10 | 6 | B1 | ||

| 4天~ | 100 | B形 | 10 | 6 | B1 | ||

| 6天~ | 120 | B形 | 10 | 6 | B1 |

Loading...

基本資訊

| 材質 | 不鏽鋼 | 熱處理 | 無 | 表面處理 | 無 |

|---|---|---|---|---|---|

| 齒研 | 無 | 間隙 | 有 | 軸承 | 無 |

| 軸孔公差 | H8 | 模數 | 1 | 精密度((級) ※新JIS) | 相當於9級 |

| 軸孔形狀 | 圓孔+攻牙 | 軸孔規格 | 標準軸孔品 | 軸孔加工 | 圓孔+2處攻牙孔 |

| 底孔品・完成品 | 完成品 | 材質(詳細) | SUS304 |

- 因有部分型號的規格・尺寸無法完全顯示,詳細資訊請參照 廠牌產品型錄 。

此分類還有這些商品

- 平齒輪 壓力角20°模數1.0

- 平齒輪 模數0.5 S45C型

- NSU 融接平齒輪

- 融接平齒輪 PU

- SS 平齒輪

- SSAY 平齒輪

- 附軸磨齒平齒輪

- F系列 SSG磨齒平齒輪 襯套一體型、摩擦固定齒輪

經常被一起購買的商品

看過此商品的人也看過這些商品

技術支援服務

- FA用機械標準零件

- Tel:02-25703766 / FAX:02-25703767

- 與我們聯絡

請協助改善本網站

請協助改善本網站

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

個人資訊保護法・隱私權政策

非常感謝您的回答。

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

希望三住回覆的客戶請使用、 與我們聯絡

個人資訊保護法・隱私權政策