(!)由於 Microsoft 2022 年 6 月 15 日終止支援,Internet Explorer 11 不屬於本網站之推薦環境。

商品分類

- 2024/12/28(六)~2025/1/5(日)適逢日本年假期間暫停出貨。 建議提早備貨以減少對交期的影響, 同時預防連假後出貨量遽增產生延遲。

#500SP1-SL1 法蘭襯套(SPF) (SPF-3525)

OILES BUSHING

可使用在無給油狀態發揮優越耐摩耗性的#500SP法蘭襯套(SPF)。

【特長】

・使用高度的鑄造技術製作的高力黃銅系合金,內含固態潤滑濟,高荷重用的無給油襯套。

・可無給油使用、在高荷重/低速運轉下發揮高性能。

・往復運動、搖擺運動等頻繁的起動停止環境下,油膜構成固難的地方能發揮優越的耐摩耗性能。

・耐藥性與耐蝕性佳。

型號

商品篩選結果為1件時,會顯示商品型號。

SPF-3525

本頁所標註的為參考用的標準出貨日。確切的預定到貨日請以訂購完成通知書的資訊為準。

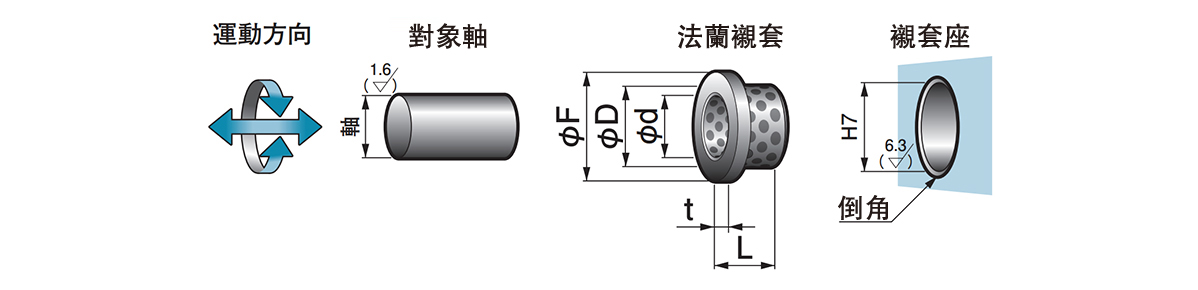

尺寸圖

(單位:mm)

#500SP1-SL1 法蘭襯套(SPF)的運動方向/對象軸、法蘭襯套、襯套座尺寸圖

軸(對象軸)種類

- d8:一般用(高負荷)

- e7一般用(輕負荷)

- f7:高精度用

- g6:高精度用(間歇運轉)

(單位:mm)

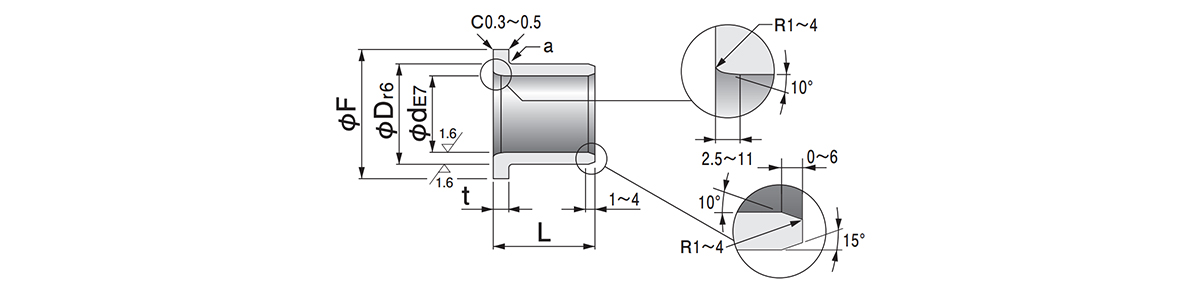

#500SP1-SL1 法蘭襯套(SPF)尺寸圖

a:頭緣下方倒角

(單位:mm)

| φd | ~18 | ~65 | ~160 |

|---|---|---|---|

| a | R0.3 | R0.5 | R1 |

- ※ SPF-6040/6050/6080/6367此4種型號為R1。

- ※ 可用於旋轉、搖動運動和往返運動。

- ※ 法蘭部未注入潤滑劑,因此無法承受推力荷重。

- ※ 請避免在海水中使用。

- ※ 內徑 31.5mm/63mm為油壓缸中間耳軸用襯套。

規格表

(單位:mm)

| 內徑 | 外徑 | 法蘭 | 長度L 公差(-0.3~-0.1) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | 公差 | φD | 公差 | φF | 公差 | t | 公差 | 10 | 12 | 15 | 17 | 18 | 20 | 23 | 25 |

| 6 | +0.032 +0.020 | 10 | +0.028 +0.019 | 16 | 0 -0.3 | 2 | 0 -0.1 | 0610 | 0612 | - | - | - | - | - | - |

| 8 | +0.040 +0.025 | 12 | +0.034 +0.023 | 20 | 0 -0.3 | 2 | 0 -0.1 | 0810 | 0812 | 0815 | - | - | - | - | - |

| 10 | +0.040 +0.025 | 14 | +0.034 +0.023 | 22 | 0 -0.3 | 2 | 0 -0.1 | 1010 | 1012 | 1015 | 1017 | - | 1020 | - | - |

| 12 | +0.050 +0.032 | 18 | +0.034 +0.023 | 25 | 0 -0.3 | 3 | 0 -0.1 | 1210 | 1212 | 1215 | - | - | 1220 | - | 1225 |

| 13 | +0.050 +0.032 | 19 | +0.041 +0.028 | 26 | 0 -0.3 | 3 | 0 -0.1 | 1310 | 1312 | 1315 | - | - | 1320 | - | 1325 |

| 14 | +0.050 +0.032 | 20 | +0.041 +0.028 | 27 | 0 -0.3 | 3 | 0 -0.1 | - | - | 1415 | - | - | 1420 | - | 1425 |

| 15 | +0.050 +0.032 | 21 | +0.041 +0.028 | 28 | 0 -0.3 | 3 | 0 -0.1 | 1510 | 1512 | 1515 | - | - | 1520 | - | 1525 |

| 16 | +0.050 +0.032 | 22 | +0.041 +0.028 | 29 | 0 -0.3 | 3 | 0 -0.1 | - | 1612 | 1615 | - | 1618 | 1620 | 1623 | 1625 |

| 18 | +0.050 +0.032 | 24 | +0.041 +0.028 | 32 | 0 -0.3 | 3 | 0 -0.1 | - | - | 1815 | - | - | 1820 | - | 1825 |

| 20 | +0.061 +0.040 | 30 | +0.041 +0.028 | 40 | 0 -0.3 | 5 | 0 -0.1 | - | - | 2015 | - | - | 2020 | - | 2025 |

| 25 | +0.061 +0.040 | 35 | +0.050 +0.034 | 45 | 0 -0.3 | 5 | 0 -0.1 | - | - | 2515 | - | - | 2520 | - | 2525 |

| 30 | +0.061 +0.040 | 40 | +0.050 +0.034 | 50 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | 3020 | - | 3025 |

| 31.5 | +0.075 +0.050 | 40 | +0.050 +0.034 | 50 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | 3120 | - | - |

| 35 | +0.075 +0.050 | 45 | +0.050 +0.034 | 60 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | 3520 | - | 3525 |

| 40 | +0.075 +0.050 | 50 | +0.050 +0.034 | 65 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | 4020 | - | 4025 |

| 45 | +0.075 +0.050 | 55 | +0.060 +0.041 | 70 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 50 | +0.075 +0.050 | 60 | +0.060 +0.041 | 75 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 55 | +0.090 +0.060 | 65 | +0.060 +0.041 | 80 | 0 -0.3 | 5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 60 | +0.090 +0.060 | 75 | +0.062 +0.043 | 90 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 63 | +0.090 +0.060 | 75 | +0.062 +0.043 | 85 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 65 | +0.090 +0.060 | 80 | +0.062 +0.043 | 95 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 70 | +0.090 +0.060 | 85 | +0.073 +0.051 | 105 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 75 | +0.090 +0.060 | 90 | +0.073 +0.051 | 110 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 80 | +0.090 +0.060 | 100 | +0.073 +0.051 | 120 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 90 | +0.107 +0.072 | 110 | +0.076 +0.054 | 130 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 100 | +0.107 +0.072 | 120 | +0.076 +0.054 | 150 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 120 | +0.107 +0.072 | 140 | +0.088 +0.063 | 170 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 130 | +0.125 +0.085 | 150 | +0.090 +0.065 | 180 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 140 | +0.125 +0.085 | 160 | +0.090 +0.065 | 190 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 150 | +0.125 +0.085 | 170 | +0.093 +0.068 | 200 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

| 160 | +0.125 +0.085 | 180 | +0.093 +0.068 | 210 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | - |

- ※ 壓入後內徑公差為參考值。

(單位:mm)

| 內徑 | 外徑 | 法蘭 | 長度L 公差(-0.3~-0.1) | 壓入後內徑公差 (參考值) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| φd | 公差 | φD | 公差 | φF | 公差 | t | 公差 | 30 | 35 | 40 | 50 | 60 | 67.5 | 80 | 100 | 120 | |

| 6 | +0.032 +0.020 | 10 | +0.028 +0.019 | 16 | 0 -0.3 | 2 | 0 -0.1 | - | - | - | - | - | - | - | - | - | +0.016 +0.004 |

| 8 | +0.040 +0.025 | 12 | +0.034 +0.023 | 20 | 0 -0.3 | 2 | 0 -0.1 | - | - | - | - | - | - | - | - | - | +0.021 +0.006 |

| 10 | +0.040 +0.025 | 14 | +0.034 +0.023 | 22 | 0 -0.3 | 2 | 0 -0.1 | - | - | - | - | - | - | - | - | - | +0.021 +0.006 |

| 12 | +0.050 +0.032 | 18 | +0.034 +0.023 | 25 | 0 -0.3 | 3 | 0 -0.1 | 1230 | - | - | - | - | - | - | - | - | +0.031 +0.013 |

| 13 | +0.050 +0.032 | 19 | +0.041 +0.028 | 26 | 0 -0.3 | 3 | 0 -0.1 | 1330 | - | - | - | - | - | - | - | - | +0.026 +0.008 |

| 14 | +0.050 +0.032 | 20 | +0.041 +0.028 | 27 | 0 -0.3 | 3 | 0 -0.1 | - | - | - | - | - | - | - | - | - | +0.026 +0.008 |

| 15 | +0.050 +0.032 | 21 | +0.041 +0.028 | 28 | 0 -0.3 | 3 | 0 -0.1 | 1530 | - | - | - | - | - | - | - | - | +0.026 +0.008 |

| 16 | +0.050 +0.032 | 22 | +0.041 +0.028 | 29 | 0 -0.3 | 3 | 0 -0.1 | 1630 | 1635 | 1640 | - | - | - | - | - | - | +0.026 +0.008 |

| 18 | +0.050 +0.032 | 24 | +0.041 +0.028 | 32 | 0 -0.3 | 3 | 0 -0.1 | 1830 | 1835 | 1840 | - | - | - | - | - | - | +0.026 +0.008 |

| 20 | +0.061 +0.040 | 30 | +0.041 +0.028 | 40 | 0 -0.3 | 5 | 0 -0.1 | 2030 | 2035 | 2040 | - | - | - | - | - | - | +0.037 +0.016 |

| 25 | +0.061 +0.040 | 35 | +0.050 +0.034 | 45 | 0 -0.3 | 5 | 0 -0.1 | 2530 | 2535 | 2540 | 2550 | - | - | - | - | - | +0.032 +0.011 |

| 30 | +0.061 +0.040 | 40 | +0.050 +0.034 | 50 | 0 -0.3 | 5 | 0 -0.1 | 3030 | 3035 | 3040 | 3050 | - | - | - | - | - | +0.032 +0.011 |

| 31.5 | +0.075 +0.050 | 40 | +0.050 +0.034 | 50 | 0 -0.3 | 5 | 0 -0.1 | 3130 | 3135 | 3140 | - | - | - | - | - | - | +0.046 +0.021 |

| 35 | +0.075 +0.050 | 45 | +0.050 +0.034 | 60 | 0 -0.3 | 5 | 0 -0.1 | 3530 | 3535 | 3540 | 3550 | - | - | - | - | - | +0.046 +0.021 |

| 40 | +0.075 +0.050 | 50 | +0.050 +0.034 | 65 | 0 -0.3 | 5 | 0 -0.1 | 4030 | 4035 | 4040 | 4050 | - | - | - | - | - | +0.046 +0.021 |

| 45 | +0.075 +0.050 | 55 | +0.060 +0.041 | 70 | 0 -0.3 | 5 | 0 -0.1 | 4530 | 4535 | 4540 | 4550 | 4560 | - | - | - | - | +0.040 +0.015 |

| 50 | +0.075 +0.050 | 60 | +0.060 +0.041 | 75 | 0 -0.3 | 5 | 0 -0.1 | 5030 | 5035 | 5040 | 5050 | 5060 | - | - | - | - | +0.040 +0.015 |

| 55 | +0.090 +0.060 | 65 | +0.060 +0.041 | 80 | 0 -0.3 | 5 | 0 -0.1 | - | - | 5540 | - | 5560 | - | - | - | - | +0.055 +0.025 |

| 60 | +0.090 +0.060 | 75 | +0.062 +0.043 | 90 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | 6040 | 6050 | 6060 | - | 6080 | - | - | +0.053 +0.023 |

| 63 | +0.090 +0.060 | 75 | +0.062 +0.043 | 85 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | - | 6367 | - | - | - | +0.053 +0.023 |

| 65 | +0.090 +0.060 | 80 | +0.062 +0.043 | 95 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | 6560 | - | - | - | - | +0.053 +0.023 |

| 70 | +0.090 +0.060 | 85 | +0.073 +0.051 | 105 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | 7050 | - | - | 7080 | - | - | +0.046 +0.016 |

| 75 | +0.090 +0.060 | 90 | +0.073 +0.051 | 110 | 0 -0.3 | 7.5 | 0 -0.1 | - | - | - | - | 7560 | - | - | - | - | +0.046 +0.016 |

| 80 | +0.090 +0.060 | 100 | +0.073 +0.051 | 120 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | 8060 | - | 8080 | 80100 | - | +0.046 +0.016 |

| 90 | +0.107 +0.072 | 110 | +0.076 +0.054 | 130 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | 9060 | - | 9080 | - | - | +0.060 +0.025 |

| 100 | +0.107 +0.072 | 120 | +0.076 +0.054 | 150 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | 10080 | 100100 | - | +0.060 +0.025 |

| 120 | +0.107 +0.072 | 140 | +0.088 +0.063 | 170 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | 12080 | 120100 | - | +0.052 +0.017 |

| 130 | +0.125 +0.085 | 150 | +0.090 +0.065 | 180 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | *13080 | *130100 | - | +0.068 +0.028 |

| 140 | +0.125 +0.085 | 160 | +0.090 +0.065 | 190 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | *14080 | *140100 | - | +0.068 +0.028 |

| 150 | +0.125 +0.085 | 170 | +0.093 +0.068 | 200 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | *150100 | *150120 | +0.065 +0.025 |

| 160 | +0.125 +0.085 | 180 | +0.093 +0.068 | 210 | 0 -0.3 | 10 | 0 -0.1 | - | - | - | - | - | - | - | *160100 | *160120 | +0.065 +0.025 |

選定用參考資訊

OILES工業 金屬系軸承 選定參考

■潤滑條件定義

(1)無潤滑、無給油

完全不使用滑脂、油等的狀態。安裝時塗抹少許滑脂、油的狀態。

(2)定期潤滑、定期給油

定期提供滑脂、油的狀態。

(3)油潤滑、強制給油

隨時對滑動面提供滑脂、油的狀態。

■適用範圍

金屬系軸承的適用範圍如下所列。

- ※ 靜態容許面壓~型錄記載文字

- ※ 環境項目的標示如右所述。○:可使用、△:依據條件可使用、×:不可使用、-:不適用

- ※在腐蝕性氣體中皆為△:依據條件可使用。

依條件分類的詳細資料可由此處確認。

技術資訊、設計概念

關於OILES軸承的設計

產品比較資訊

| 類型 | #500SP1-SL1 | #500SP1-SL4 | #500SP5-SL1 | #500HP-SL1 | #500B-SL2 | #500F-SL1 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 代表產品 |  SPB |  SPBL |  SP5B |  HPB |  BCB |  FGB | |||||

| 用途 | 一般 中、高荷重用 | 一般 中、高荷重用 | 高荷重 低、中速用 | 高荷重 低、中速用 | 一般 中荷重用 | 低速 低、中荷重用 | |||||

| 基底金屬 | 高強度黃銅類鑄件 | 高強度黃銅類鑄件 | 特殊高強度黃銅類鑄件 | 高硬度特殊銅合金鑄件 | 青銅類鑄件 | 鑄鐵 | |||||

| 潤滑條件 | 無潤滑 | 定期潤滑 | 無潤滑 | 無潤滑 | 定期潤滑 | 無潤滑 | 定期潤滑 | 無潤滑 | 定期潤滑 | 無潤滑 | 定期潤滑 |

| 使用溫度範圍 ℃ | -40~+300 | -40~+150 | -40~+80 | -40~+150 | -40~+150 | -40~+250 | -40~+150 | -40~+400 | -40~+150 | ||

| 容許最高面壓 P N/mm2{kgf/cm2} | 29 {296} ※150 {1530} | 49 {500} ※150 {1530} | 49 {500} ※170 {1735} | 73 {745} ※180 {1837} | 15 {153} ※49 {500} | 5 {51} ※73.5 {750} | 8 {82} ※73.5 {750} | ||||

| 容許最高速度 V m/s{m/min} | 0.50 {30} | 1.00 {60} | 0.25 {15} | 0.25 {15} | 0.50 {30} | 0.10 {6} | 0.25 {15} | 0.40 {24} | 0.85 {51} | 0.15 {9} | 0.25 {15} |

| 容許最高 PV值 N/mm2 ・ m/s {kgf/cm2 ・ m/min} | 1.65 {1010} | 3.25 {1990} | 1.65 {1010} | 1.65 {1010} | 3.25 {1990} | 1.65 {1010} | 3.25 {1990} | 1.00 {612} | 1.65 {1010} | 0.5 {306} | 0.8 {490} |

| 大氣中 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 水中 | × | - | ○ | × | - | × | - | △ | - | △ | - |

| 海水中 | × | - | △ | × | - | × | - | △ | - | × | - |

| 藥液中 | × | - | △ | × | - | × | - | △ | - | △ | - |

| 腐蝕性氣體中 | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ | △ |

( )為靜態容許面壓:代表沒有滑動,或是以參考值為0.0017m/s{0.1m/min}以下的極低速度滑動時的容許面壓。

| 型號 |

|---|

| SPF-3525 |

| 型號 | 數量折扣 | 標準 出貨日 | 內徑 d (φ) | 外徑 D (φ) | 全長 L (mm) | 法蘭外徑 (mm) |

|---|---|---|---|---|---|---|

| 4天~ | 35 | 45 | 25 | 60 |

Loading...

基本資訊

| 型式 | 法蘭 | 金屬類 | 黃銅 | 使用環境 | 標準 / 耐熱 / 耐異物 |

|---|---|---|---|---|---|

| 容許最高PV值範圍(N/mm2・m/s) | 1.1~2.0 | 容許最高PV值(N/mm2・m/s) | 1.65 | 容許最高面壓 P(N/mm2) | 29 |

| 容許最高速度 V(m/s) | 0.5 | 長度種類 | 標準 | 安裝軸嵌合 | e7 |

| 安裝孔嵌合 | H7 | 潤滑條件 | 無潤滑 | 使用溫度範圍(℃) | -40::300 |

#500SP1-SL1 法蘭襯套(SPF)的型號SPF-3525頁面。

記載關於型號SPF-3525之規格、尺寸、型式情報。

篩選規格・尺寸

-

類型

- SPF

-

內徑 d(φ)

-

外徑 D(φ)

-

全長 L(mm)

-

法蘭外徑(mm)

-

CAD檔案

- 2D

- 3D

用出貨日篩選

-

- 全選

- 4天以内

- 7天以内

- 8天以内

- 10天以内

- 11天以内

- 16天以内

- 44天以内

可指定追加工

- 因有部分型號的規格・尺寸無法完全顯示,詳細資訊請參照 廠牌產品型錄 。

本商品分類

| 型號 |

|---|

| SPF-0812 |

| SPF-0815 |

| SPF-10080 |

| SPF-3530 |

| SPF-3535 |

| SPF-3540 |

| 型號 | 數量折扣 | 標準 出貨日 | 內徑 d (φ) | 外徑 D (φ) | 全長 L (mm) | 法蘭外徑 (mm) |

|---|---|---|---|---|---|---|

| 4天~ | 8 | 12 | 12 | 20 | ||

| 4天~ | 8 | 12 | 15 | 20 | ||

| 4天~ | 100 | 120 | 80 | 150 | ||

| 4天~ | 35 | 45 | 30 | 60 | ||

| 4天~ | 35 | 45 | 35 | 60 | ||

| 4天~ | 35 | 45 | 40 | 60 |

此分類還有這些商品

- 無給油襯套 青銅標準法蘭型

- 無給油襯套 銅合金標準/薄壁內徑G6

- 無給油襯套 POM樹脂 直柱型

- 無給油襯套 PTFE樹脂型 直柱型

- 【經濟型】無給油襯套座組 二面法蘭型

- 【經濟型】無給油襯套 法蘭一體成型 銅合金中央法蘭型

- 金屬陶瓷M襯套(54B)

- ARF型 附法蘭套筒軸承

經常被一起購買的商品

看過此商品的人也看過這些商品

技術支援服務

- FA用機械標準零件

- Tel:02-25703766 / FAX:02-25703767

- 與我們聯絡

請協助改善本網站

請協助改善本網站

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

個人資訊保護法・隱私權政策

非常感謝您的回答。

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

希望三住回覆的客戶請使用、 與我們聯絡

個人資訊保護法・隱私權政策