(!)由於 Microsoft 2022 年 6 月 15 日終止支援,Internet Explorer 11 不屬於本網站之推薦環境。

商品分類

- 於2024/11/24 9:00 ~ 11/25 7:00 期間,由於進行網站例行維護將無法使用此網站,不便之處尚祈見諒。

磨齒平齒輪 模數0.5(SCM415、SCM440)

高強度、耐磨耗性優異的JIS N5的高精度磨齒平齒輪。

【特長】

・由於齒部經過高頻淬火,具高強度且耐磨耗性優異。

・材質SCM435、440。

・由於僅有齒部經淬火,因此齒部以外可進行鍵槽或攻牙、孔徑變更等追加工。

・由於孔、齒部外圍、兩側面皆經磨削加工,因此可作為追加工的基準面。

・齒輪精度等級為JIS B 1702-1(ISO)5級。

・形狀為L:附兩軸、B:附單轂。

【用途】

・裝置的動力傳導、驅動、輸送部分。可用高精度傳導。

型號

商品篩選結果為1件時,會顯示商品型號。

本頁所標註的為參考用的標準出貨日。確切的預定到貨日請以訂購完成通知書的資訊為準。

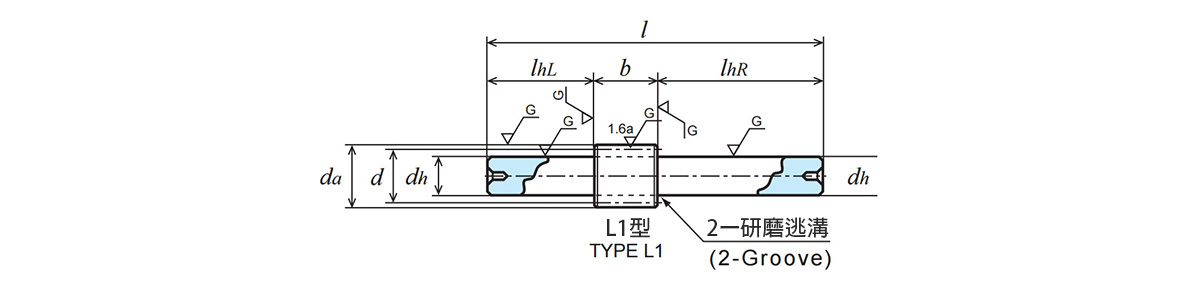

尺寸圖

產品規格

容許傳導動力表

彎曲強度

| 齒數 z | 齒寬 b | 彎曲強度(kW) | ||||||

|---|---|---|---|---|---|---|---|---|

| 旋轉速度(min-1) | ||||||||

| 400 | 800 | 1,200 | 1,500 | 1,800 | 2,500 | 3,000 | ||

| 20 | 8 | 108.04 | 216.08 | 324.12 | 405.15 | 486.18 | 675.25 | 810.30 |

| 22 | 8 | 124.31 | 248.63 | 372.94 | 466.17 | 559.41 | 776.95 | 932.34 |

| 24 | 8 | 140.85 | 281.70 | 422.54 | 528.18 | 633.81 | 880.30 | 1,056.36 |

| 25 | 8 | 149.23 | 298.46 | 447.69 | 559.61 | 671.53 | 932.68 | 1,119.22 |

| 26 | 8 | 157.67 | 315.34 | 473.01 | 591.26 | 709.51 | 985.43 | 1,182.52 |

| 28 | 8 | 174.71 | 349.41 | 524.12 | 655.15 | 786.18 | 1,091.91 | 1,310.30 |

| 30 | 8 | 191.83 | 383.66 | 575.50 | 719.37 | 863.24 | 1,198.95 | 1,438.74 |

| 32 | 8 | 209.19 | 418.38 | 627.57 | 784.46 | 941.35 | 1,307.43 | 1,568.92 |

| 35 | 8 | 235.49 | 470.97 | 706.46 | 883.07 | 1,059.69 | 1,471.79 | 1,766.14 |

| 36 | 8 | 244.32 | 488.63 | 732.95 | 916.18 | 1,099.42 | 1,526.97 | 1,832.36 |

| 40 | 8 | 279.89 | 559.78 | 839.67 | 1,049.58 | 1,259.50 | 1,749.30 | 2,091.76 |

| 42 | 8 | 297.82 | 595.64 | 893.46 | 1,116.83 | 1,340.19 | 1,861.38 | 2,217.10 |

| 44 | 8 | 315.62 | 631.24 | 946.87 | 1,183.58 | 1,420.30 | 1,972.64 | 2,340.50 |

| 45 | 8 | 324.64 | 649.28 | 973.91 | 1,217.39 | 1,460.87 | 2,028.99 | 2,402.69 |

| 48 | 8 | 351.79 | 703.58 | 1,055.38 | 1,319.22 | 1,583.07 | 2,190.95 | 2,588.62 |

| 50 | 8 | 369.97 | 739.94 | 1,109.91 | 1,387.38 | 1,664.86 | 2,296.66 | 2,711.92 |

| 52 | 8 | 388.21 | 776.41 | 1,164.62 | 1,455.78 | 1,746.93 | 2,402.07 | 2,834.73 |

| 54 | 8 | 406.49 | 812.98 | 1,219.47 | 1,524.34 | 1,829.21 | 2,507.08 | 2,956.93 |

| 55 | 8 | 415.65 | 831.31 | 1,246.96 | 1,558.70 | 1,870.44 | 2,559.46 | 3,017.83 |

| 56 | 8 | 424.83 | 849.65 | 1,274.47 | 1,593.09 | 1,911.71 | 2,611.72 | 3,078.57 |

| 60 | 8 | 461.62 | 923.25 | 1,384.87 | 1,731.08 | 2,077.30 | 2,819.79 | 3,320.04 |

| 64 | 8 | 498.57 | 997.13 | 1,495.70 | 1,869.62 | 2,242.66 | 3,023.11 | 3,559.67 |

| 70 | 8 | 554.23 | 1,108.46 | 1,662.69 | 2,078.37 | 2,475.56 | 3,332.20 | 3,927.74 |

| 72 | 8 | 572.84 | 1,145.69 | 1,178.53 | 2,148.17 | 2,552.72 | 3,433.30 | 4,049.63 |

| 75 | 8 | 600.84 | 1,201.61 | 1,802.41 | 2,253.02 | 2,667.98 | 3,584.01 | 4,231.63 |

| 80 | 8 | 647.54 | 1,295.08 | 1,942.62 | 2,419.70 | 2,858.90 | 3,839.99 | 4,532.93 |

| 90 | 8 | 740.43 | 1,480.87 | 2,221.30 | 2,740.03 | 3,231.68 | 4,345.90 | 5,120.65 |

| 96 | 8 | 796.77 | 1,593.54 | 2,389.35 | 2,931.46 | 3,453.87 | 4,647.97 | 5,470.63 |

| 100 | 8 | 834.38 | 1,668.76 | 2,494.32 | 3,058.06 | 3,600.58 | 4,847.65 | 5,701.55 |

| 108 | 8 | 909.75 | 1,819.50 | 2,702.70 | 3,308.89 | 3,893.39 | 5,243.00 | 6,135.59 |

| 112 | 8 | 947.51 | 1,895.02 | 2,806.16 | 3,433.16 | 4,042.91 | 5,438.74 | 6,345.45 |

| 120 | 8 | 1,023.12 | 2,046.24 | 3,011.40 | 3,679.20 | 4,339.67 | 5,826.04 | 6,757.02 |

齒面強度

| 齒數 z | 齒寬 b | 齒面強度(kW) | ||||||

|---|---|---|---|---|---|---|---|---|

| 旋轉速度(min-1) | ||||||||

| 400 | 800 | 1,200 | 1,500 | 1,800 | 2,500 | 3,000 | ||

| 20 | 8 | 25.17 | 50.59 | 76.25 | 95.65 | 115.17 | 161.15 | 194.36 |

| 22 | 8 | 30.61 | 61.55 | 92.81 | 116.45 | 140.25 | 196.36 | 236.91 |

| 24 | 8 | 36.59 | 73.62 | 111.05 | 139.38 | 167.91 | 235.22 | 283.88 |

| 25 | 8 | 39.79 | 80.07 | 120.81 | 151.65 | 182.72 | 256.03 | 309.05 |

| 26 | 8 | 43.13 | 86.81 | 131.00 | 164.46 | 198.18 | 277.76 | 335.34 |

| 28 | 8 | 50.22 | 101.12 | 152.66 | 191.71 | 231.06 | 324.02 | 391.30 |

| 30 | 8 | 57.86 | 116.57 | 176.05 | 221.13 | 266.60 | 374.03 | 451.82 |

| 32 | 8 | 66.06 | 133.15 | 201.17 | 252.76 | 304.79 | 427.81 | 516.93 |

| 35 | 8 | 79.42 | 160.18 | 242.14 | 304.34 | 367.11 | 515.63 | 623.27 |

| 36 | 8 | 84.16 | 169.76 | 256.68 | 322.65 | 389.24 | 546.82 | 661.05 |

| 40 | 8 | 104.51 | 211.00 | 319.25 | 401.49 | 484.56 | 681.25 | 821.03 |

| 42 | 8 | 115.54 | 233.37 | 353.22 | 444.30 | 536.33 | 754.32 | 905.72 |

| 44 | 8 | 127.15 | 256.91 | 388.98 | 489.39 | 590.86 | 831.31 | 994.49 |

| 45 | 8 | 133.17 | 269.12 | 407.53 | 512.79 | 619.17 | 871.29 | 1,040.39 |

| 48 | 8 | 152.08 | 307.52 | 465.92 | 586.43 | 708.29 | 993.65 | 1,184.13 |

| 50 | 8 | 165.41 | 334.61 | 507.12 | 638.42 | 771.20 | 1,078.73 | 1,284.96 |

| 52 | 8 | 179.32 | 362.89 | 550.15 | 692.72 | 836.93 | 1,167.23 | 1,389.78 |

| 54 | 8 | 193.81 | 392.37 | 595.01 | 749.36 | 905.50 | 1,259.13 | 1,498.55 |

| 55 | 8 | 201.28 | 407.56 | 618.14 | 778.55 | 940.85 | 1,306.36 | 1,554.41 |

| 56 | 8 | 208.89 | 423.05 | 641.73 | 808.33 | 976.92 | 1,354.43 | 1,611.25 |

| 60 | 8 | 240.80 | 488.02 | 740.72 | 933.35 | 1,128.33 | 1,555.13 | 1,848.36 |

| 64 | 8 | 275.06 | 557.86 | 847.18 | 1,067.84 | 1,290.76 | 1,769.21 | 2,101.33 |

| 70 | 8 | 330.89 | 671.79 | 1,020.99 | 1,287.52 | 1,545.96 | 2,115.13 | 2,518.03 |

| 72 | 8 | 350.69 | 712.23 | 1,082.72 | 1,365.57 | 1,636.03 | 2,236.98 | 2,665.11 |

| 75 | 8 | 381.51 | 775.21 | 1,178.89 | 1,487.18 | 1,775.81 | 2,425.83 | 2,893.33 |

| 80 | 8 | 435.87 | 886.40 | 1,348.78 | 1,696.04 | 2,021.16 | 2,761.77 | 3,293.88 |

| 90 | 8 | 555.93 | 1,132.30 | 1,724.83 | 2,149.18 | 2,557.83 | 3,501.66 | 4,169.72 |

| 96 | 8 | 635.27 | 1,295.04 | 1,973.12 | 2,446.11 | 2,908.90 | 3,986.43 | 4,742.36 |

| 100 | 8 | 691.23 | 1,409.92 | 2,142.24 | 2,654.41 | 3,154.91 | 4,326.43 | 5,143.47 |

| 108 | 8 | 810.54 | 1,655.11 | 2,500.92 | 3,095.63 | 3,677.90 | 5,046.42 | 5,969.89 |

| 112 | 8 | 873.91 | 1,785.46 | 2,690.44 | 3,328.44 | 3,958.21 | 5,426.21 | 6,400.03 |

| 120 | 8 | 1,008.14 | 2,061.81 | 3,089.65 | 3,818.25 | 4,549.00 | 6,224.91 | 7,298.89 |

規格表

單位:mm

| 型號 | 齒數 | 基準圓 直徑 d | 齒尖圓 直徑 da | 型 | 齒寬 b | 孔徑 dd(H7) | 轂 外徑 dh | 轂 長度 lh | 全長 l | 螺絲 | 鑽孔 dr | 重量 W(g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | ls | ||||||||||||

| SG50S 20L-0806 | 20 | φ10 | φ11 | L1 | 8 | - | φ6(h7) | L22 R50 | 80 | - | - | - | 20.8 |

| SG50S 22L-0808 | 22 | φ11 | φ12 | L1 | 8 | - | φ8(h7) | L22 R50 | 80 | - | - | - | 34.2 |

| SG50S 24L-0810 | 24 | φ12 | φ13 | L1 | 8 | - | φ10(h7) | L22 R50 | 80 | - | - | - | 51.1 |

| SG50S 25L-0810 | 25 | φ12.5 | φ13.5 | L1 | 8 | - | φ10(h7) | L22 R50 | 80 | - | - | - | 51.7 |

| SG50S 26L-0810 | 26 | φ13 | φ14 | L1 | 8 | - | φ10(h7) | L22 R50 | 80 | - | - | - | 52.4 |

| SG50S 28B-0805 | 28 | φ14 | φ15 | B1 | 8 | φ5 | φ10 | 8 | 16 | - | - | - | 12.1 |

| SG50S 30B-0805 | 30 | φ15 | φ16 | B1 | 8 | φ5 | φ12 | 8 | 16 | - | - | - | 15.6 |

| SG50S 30B-0806 | 30 | φ15 | φ16 | B1 | 8 | φ6 | φ12 | 8 | 16 | - | - | - | 14.5 |

| SG50S 30B*0806 | 30 | φ15 | φ16 | B1 | 8 | φ6 | φ12 | 8 | 16 | 2-M3 | 4 | - | 14.4 |

| SG50S 32B-0805 | 32 | φ16 | φ17 | B1 | 8 | φ5 | φ12 | 8 | 16 | - | - | - | 17.2 |

| SG50S 32B-0806 | 32 | φ16 | φ17 | B1 | 8 | φ6 | φ12 | 8 | 16 | - | - | - | 16.1 |

| SG50S 35B-0805 | 35 | φ17.5 | φ18.5 | B1 | 8 | φ5 | φ14 | 8 | 16 | - | - | - | 22.2 |

| SG50S 36B-0806 | 36 | φ18 | φ19 | B1 | 8 | φ6 | φ16 | 8 | 16 | - | - | - | 24.9 |

| SG50S 36B-0808 | 36 | φ18 | φ19 | B1 | 8 | φ8 | φ16 | 8 | 16 | - | - | - | 22.1 |

| SG50S 40B-0806 | 40 | φ20 | φ21 | B1 | 8 | φ6 | φ16 | 8 | 16 | - | - | - | 28.6 |

| SG50S 40B-0808 | 40 | φ20 | φ21 | B1 | 8 | φ8 | φ16 | 8 | 16 | - | - | - | 25.9 |

| SG50S 40B*0808 | 40 | φ20 | φ21 | B1 | 8 | φ8 | φ16 | 8 | 16 | 2-M4 | 4 | - | 25.5 |

| SG50S 45B-0808 | 45 | φ22.5 | φ23.5 | B1 | 8 | φ8 | φ16 | 8 | 16 | - | - | - | 31.1 |

| SG50S 48B-0808 | 48 | φ24 | φ25 | B1 | 8 | φ8 | φ20 | 8 | 16 | - | - | - | 34.5 |

| SG50S 50B-0808 | 50 | φ25 | φ26 | B1 | 8 | φ 8 | φ20 | 8 | 16 | - | - | - | 43.9 |

| SG50S 50B-0810 | 50 | φ25 | φ26 | B1 | 8 | φ10 | φ20 | 8 | 16 | - | - | - | 40.4 |

| SG50S 50B*0810 | 50 | φ25 | φ26 | B1 | 8 | φ10 | φ20 | 8 | 16 | 2-M4 | 4 | - | 40 |

| SG50S 54B-0808 | 54 | φ27 | φ28 | B1 | 8 | φ 8 | φ20 | 8 | 16 | - | - | - | 49 |

| SG50S 55B-0808 | 55 | φ27.5 | φ28.5 | B1 | 8 | φ 8 | φ20 | 8 | 16 | - | - | - | 50.4 |

| SG50S 56B-0808 | 56 | φ28 | φ29 | B1 | 8 | φ 8 | φ20 | 8 | 16 | - | - | - | 51.7 |

| SG50S 60B-0808 | 60 | φ30 | φ31 | B1 | 8 | φ 8 | φ22 | 8 | 16 | - | - | - | 61.5 |

| SG50S 60B-0810 | 60 | φ30 | φ31 | B1 | 8 | φ10 | φ22 | 8 | 16 | - | - | - | 58 |

| SG50S 60B*0810 | 60 | φ30 | φ31 | B1 | 8 | φ10 | φ22 | 8 | 16 | 2-M4 | 4 | - | 57.6 |

| SG50S 64B-0808 | 64 | φ32 | φ33 | B1 | 8 | φ 8 | φ22 | 8 | 16 | - | - | - | 67.6 |

| SG50S 70B-0808 | 70 | φ35 | φ36 | B1 | 8 | φ 8 | φ22 | 8 | 16 | - | - | - | 77.4 |

| 型號 | 齒數 | 基準圓 直徑 d | 齒尖圓 直徑 da | 型 | 齒寬 b | 孔徑 dd(H7) | 轂 外徑 dh | 轂 長度 lh | 全長 l | 螺絲 | 鑽孔 dr | 重量 W(g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | ls | ||||||||||||

| SG50S72B-0808 | 72 | φ36 | φ37 | B1 | 8 | φ8 | φ25 | 8 | 16 | - | - | - | 87.8 |

| SG50S75B-0808 | 75 | φ37.5 | φ38.5 | B1 | 8 | φ8 | φ25 | 8 | 16 | - | - | - | 93.2 |

| SG50S80B-0808 | 80 | φ40 | φ41 | B1 | 8 | φ8 | φ25 | 8 | 16 | - | - | - | 102.7 |

| SG50S80B-0810 | 80 | φ40 | φ41 | B1 | 8 | φ10 | φ25 | 8 | 16 | - | - | - | 99.2 |

| SG50S80B-0812 | 80 | φ40 | φ41 | B1 | 8 | φ12 | φ25 | 8 | 16 | - | - | - | 94.9 |

| SG50S80B*0812 | 80 | φ40 | φ41 | B1 | 8 | φ12 | φ25 | 8 | 16 | 2-M5 | 4 | - | 94.1 |

| SG50S90B-0810 | 90 | φ45 | φ46 | B1 | 8 | φ10 | φ30 | 8 | 16 | - | - | - | 133.5 |

| SG50S96B-0810 | 96 | φ48 | φ49 | B1 | 8 | φ10 | φ30 | 8 | 16 | - | - | - | 147.1 |

| SG50S100B-0810 | 100 | φ50 | φ51 | B1 | 8 | φ10 | φ30 | 8 | 16 | - | - | - | 156.7 |

| SG50S100B-0812 | 100 | φ50 | φ51 | B1 | 8 | φ12 | φ30 | 8 | 16 | - | - | - | 152.4 |

| SG50S100B*0812 | 100 | φ50 | φ51 | B1 | 8 | φ12 | φ30 | 8 | 16 | 2-M5 | 4 | - | 151.5 |

| SG50S108B-0810 | 108 | φ54 | φ55 | B1 | 8 | φ10 | φ35 | 8 | 16 | - | - | - | 193.0 |

| SG50S112B-0810 | 112 | φ56 | φ57 | B1 | 8 | φ10 | φ35 | 8 | 16 | - | - | - | 203.8 |

| SG50S120B-0810 | 120 | φ60 | φ61 | B1 | 8 | φ10 | φ35 | 8 | 16 | - | - | - | 226.6 |

- ※未附固定螺絲。

| 型號 |

|---|

| SG50S36B-0808 |

| SG50S60B-0810 |

| 型號 | 數量折扣 | 標準 出貨日 | 齒數 (齒) | 軸孔徑、軸徑 d (φ) |

|---|---|---|---|---|

| 4天~ | 36 | 8 | ||

| 4天~ | 60 | 10 |

Loading...

基本資訊

| 材質 | 一般鐵鋼材 | 形狀 | B形 | 熱處理 | 高頻 |

|---|---|---|---|---|---|

| 表面處理 | 無 | 齒研 | 有 | 間隙 | 有 |

| 軸承 | 無 | 齒寬 B(mm) | 8 | 軸孔公差 | H7 |

| 模數 | 0.5 | 精密度((級) ※新JIS) | 相當於5級 | 軸孔形狀 | 圓孔 |

| 軸孔規格 | 標準軸孔品 | 軸孔加工 | 圓孔車削加工 | 底孔品・完成品 | 底孔品 |

| 材質(詳細) | SCM415/SCM440 | 形狀(詳細) | B1 |

- 因有部分型號的規格・尺寸無法完全顯示,詳細資訊請參照 廠牌產品型錄 。

此分類還有這些商品

- 平齒輪 壓力角20°模數3.0

- 平齒輪 模數0.5 黃銅型

- 平齒輪 模數3 S45C型

- 不鏽鋼平齒輪 模數0.8

- SSG 磨齒平齒輪

- DSF F快鎖正齒輪

- F系列 SSA平齒輪 襯套一體型、摩擦固定齒輪

- 平齒輪 m1 POM 藍(聚甲醛)型

經常被一起購買的商品

看過此商品的人也看過這些商品

技術支援服務

- FA用機械標準零件

- Tel:02-25703766 / FAX:02-25703767

- 與我們聯絡

請協助改善本網站

請協助改善本網站

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

個人資訊保護法・隱私權政策

非常感謝您的回答。

對於各位顧客的寶貴意見請恕我們無法逐一回覆,還請諒解。

希望三住回覆的客戶請使用、 與我們聯絡

個人資訊保護法・隱私權政策